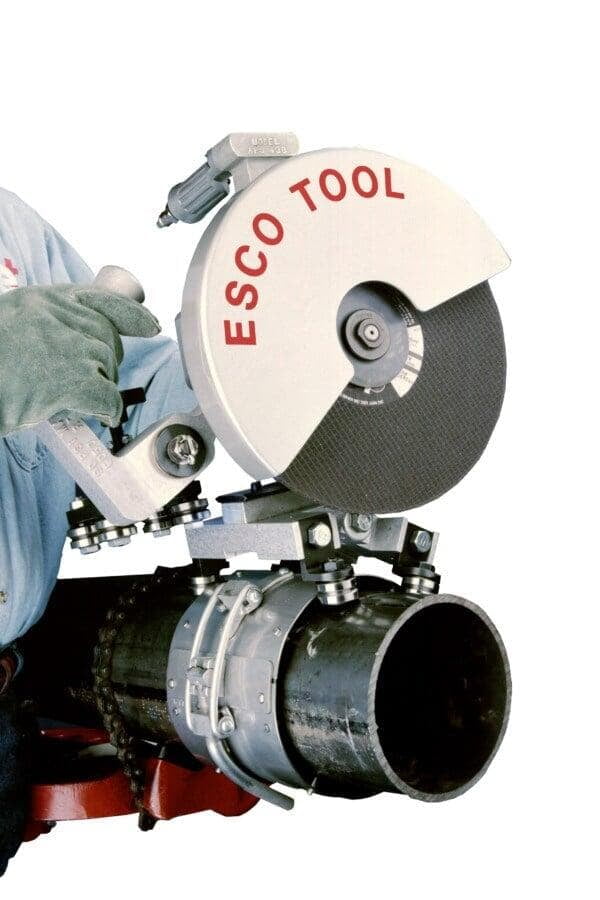

Split-Frame Prepping and Cutting Tool

Split-Frame Prepping and Cutting Tool

The ESCO Split-Frame Prepping and Cutting Tool, also known as the COHOG® clamshell machine, is designed for precision and efficiency in cutting and beveling operations on pipes and tubes. This robust tool features a modular setup that allows for quick and easy adjustments, catering to a range of diameters from 2” to 48” (50.8mm to 1219.2mm).

Key Features:

- Durable Construction: Built with a stationary ring made from 7075 aluminum alloy and a rotating ring from custom steel forgings, this tool ensures maximum strength and durability, even in the toughest environments.

- Precision and Versatility: The COHOG® utilizes indexable tool slides and a trip mechanism with a marked locating system, enabling precise alignments and quick setups without the need for shims.

- Ease of Use: Self-squaring clamp legs ensure the machine is rigid enough to part and bevel heavy wall pipes without vibration or chatter, enhancing operational efficiency and cutting quality.

- Motor Options: Available with pneumatic, hydraulic, or electric motors to suit different job requirements and site conditions.

Benefits:

- Enhanced Performance: The precision-tuned bearings and robust design allow for smooth cutting action on any material, reducing downtime and increasing productivity.

- Cost-Effective: The modular blade system can use conventional high-speed tool steel blades or cutting inserts, which offer multiple cutting edges, providing more cuts per blade at a lower cost.

The ESCO Split-Frame Prepping and Cutting Tool is ideal for professionals seeking reliable, high-performance equipment for complex pipe and tube fabrication tasks.

Flange Hog

Flange Hog

The ESCO FLANGE HOG® 110 is a versatile and easy-to-use manual flange facing tool designed to restore damaged raised-face and flat-face flanges to like-new condition. This tool eliminates the need for cutting and replacing flanges, making it ideal for field repairs and maintenance.

Key Features:

- Ease of Use: The FLANGE HOG 110 mounts to the flange ID in seconds with a clamping range of 0.9” to 10” and ensures a precise alignment with 0.005” accuracy.

- Wide Reach: Capable of machining flanges up to 14” O.D., it is suitable for a variety of flange sizes.

- Dual-Use Cutting Bits: Equipped with straight and 90-degree tool bit holders, the cutting bits are double-sided and designed to handle highly alloyed materials.

- Precision Finish: Produces a phonographic finish that meets ASME B16.5 standards, ensuring high-quality surface finishes on gasket seats.

Benefits:

- Field-Friendly: The FLANGE HOG 110's manual operation allows it to be used virtually anywhere, making it perfect for on-site process piping repairs.

- Cost-Effective: By eliminating the need for flange replacement, it saves time and costs associated with pipe cutting, welding, and inspection.

The ESCO FLANGE HOG® 110 is an essential tool for professionals looking to maintain and repair flanges efficiently and effectively in the field.

Pneumatic End Prep Tool

Pneumatic End Prep Tool

The ESCO Wart Millhog is a highly portable right-angle I.D. clamping tool designed for precision beveling, facing, and boring of pipe and tube ends. This versatile machine is perfect for preparing boiler tubes and other pipes for welding, particularly in confined spaces such as boiler tube waterwalls.

Key Features:

- Compact Design: At only 2.625 inches wide, the Wart Millhog fits easily between tubes in tight working environments.

- Precision and Versatility: Capable of beveling, facing, and boring simultaneously with ± 0.001” accuracy, it ensures perfectly square pipe ends for better weld integrity.

- Durable Construction: Incorporates a heavy-duty gear drive supported by dual opposed tapered roller bearings and three heavy-duty ball bearings, ensuring long-term reliability and minimal maintenance.

- Powerful Motor Options: Available with both pneumatic and electric motors, providing flexibility for different job site requirements.

- Ease of Use: Features a self-centering draw rod assembly and a mandrel with expanding clamps for quick, rigid mounting, enhancing ease of setup and operation.

Benefits:

- Field-Friendly: The portable design and robust performance make it ideal for on-site use, particularly in the oil and gas, nuclear, hydro-electric, and power plant industries.

- Cost-Effective: The tool's efficiency in preparing multiple tube ends for welding in one go reduces downtime and increases productivity.

Pres Tech's end prep tools deliver unmatched precision and efficiency, ensuring perfect pipe preparations for any project.